Building a YR2006 "Second Lebanon War" Sufa

- Yoav Efrati

- Jul 30, 2020

- 13 min read

Updated: Aug 2, 2025

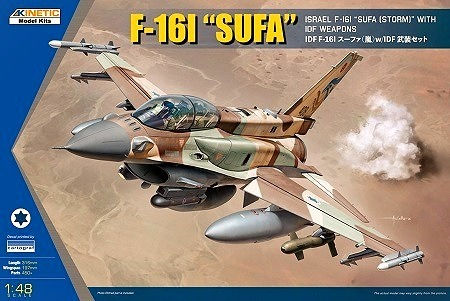

Kinetic's 1/48 scale F-16i Sufa, kit no.6

Kinetic's 1/48 scale kit of the Israeli air force F-16i Sufa hit the modeling world with great fan fare 11 years ago. The kit's current year 2020 reissue, updates the weapons fit for the Sufa, yet still requires fuselage nose section shape and detail corrections detailed in this article.

Meet the Sufa:

The Israeli Air and Space Force (IASF) hottest fighter is the Lockheed Martin block 52 version of the F-16D, known in Israel as the F-16i Sufa ("storm" in Hebrew). The Sufa is a block 52 F-16D and the 52 designation stands for the Pratt & Whitney F-100-PW-229 engine. The engine airflow requirements differ from those of the General Electric F110 engine enabling the Sufa to retain the F-16's original small intake.

With a full external fuel tank fit, the range of the Sufa is comparable to that of the twin engine F-15i Strike Eagle. Setting the IASF Sufa apart from other versions of the F-16 throughout the world is its indigenous developed Elisra ECM/RWR suite, Rafael secure communications gear, Rada digital data link, Rafael Lightning recon & targeting pods, Elbit Dash IV helmet mounted display.

The Sufa is capable of delivering the same air to air and air to ground ordnance as the Eagle with the exception of non standard ordnance such as the GBU-28 Bunker Buster. External ordnance carried by the Sufa include the Raytheon AIM-120 radar guided missile, Rafael IR guided air to air Python 4 & 5 missile, Raytheon AIM-9L/M Sidewinder, Rafael Spice GPS/Optically guided glide bomb Mk.83 & Mk.84, Israeli Military Industries Delila "cruise missile", Paveway II-Mk.82, 83 & 84 laser guided bombs, GBU-15(V)21/B + AN/AXQ-14 data link, Mk.84 and Mk.83 bombs fitted with JDAM guidance kits, GBU-38 500-lbs warhead bombs (introduced during Dec08-Jan09 operation "Cast Lead" in Gaza), Lockheed Martin AN/AAQ/13 Lantrin navigation pod, Rafael Lightning II targeting pod, 300 gallon center line, 370 gallon wing and 600 gallon wing external fuel tanks.

The Sufa's chaff/flare dispenser arrangement differs from those of the Netz and Barak. The Sufa has a single dispenser on the aft right hand side of the aft fuselage and three dispensers on the aft left hand side of the aft fuselage. On the upper fuselage hump fairing, it has two dispensers on each side.

Sufa Squadron Photo Album:

The IASF distributed 102 Sufa F-16i's to four squadrons. The first squadron to operate the Sufa was the Negev squadron who received their 400 series fighters on 19 February 2004, followed by the Bat squadron on 28 December 2004. The third and fourth Sufa squadrons received 800 series F-16i's were the Orange Tail squadron who opened on 05 July 2006 followed by the Ahat squadron two years later, on 09 July 2008.

Each Sufa squadron adopted different tail markings as chosen by the air and ground personnel of the squadron. The Negev squadron adopted their tail markings only after their sister squadron adopted a Bat for the fin markings at the end of 2004.

By the time the summer 2006 Second Lebanon War broke out, the first three squadrons were operational sporting their current tail fin markings. When the Second Lebanon War broke out, Orange tail squadron pilots flew Sufa aircraft loaned to them by the Negev and Bat squadrons which made for a very pretty line up. By the time Operation Cast Lead broke out on 27 December 2008, the Ahat squadron was not combat qualified and was integrated to operate with Negev and Bat squadrons operating from the same base. The last four, of the 102 Sufa aircraft ordered by the IASF, tail numbers 893 (s/n 99-9448), 894 (99-9449), 896 (99-9450), 898 (99-9451), arrived in Israel the first quarter of 2009 and transferred to the Ahat squadron.

Sufa Colors:

Sufa colors are a mix of US federal standard 595b colors and Israel's Tambor paints. New delivered aircraft are painted f.s.36375 light ghost gray under surface with f.s.30219 brown, f.s.34424 green and f.s.33531 sand upper surface colors with f.s.36270 gray radome and antenna fairings. The conformal fuel tanks are made in Israel by Israel Aircraft Industries and are painted using Tambor paints. This is most noticeable in the different brown shade used by Tambor which is a bid more red than the US standard color. When painting the Sufa, use Humbrol 118 brown for the fuselage with Humbrol 119 for the CFT. For the green and light ghost gray I prefer Testor Model Master Sky Type S and f.s.36375. For the sand I prefer to use Xtracolor X105 sand. Please note that the leading edge of the CFT is painted gloss green f.s.14424 for aerodynamic smoothness requirements. The Sufa cockpit side walls are painted f.s.36231 (Humbrol 140) with black side consoles, instrument panel and dash boards. The Aces II ejection seats are painted f.s.36231 gray with black sheep's wool cushion covers.

Building Kinetic's 1/48 Scale F-16i Sufa

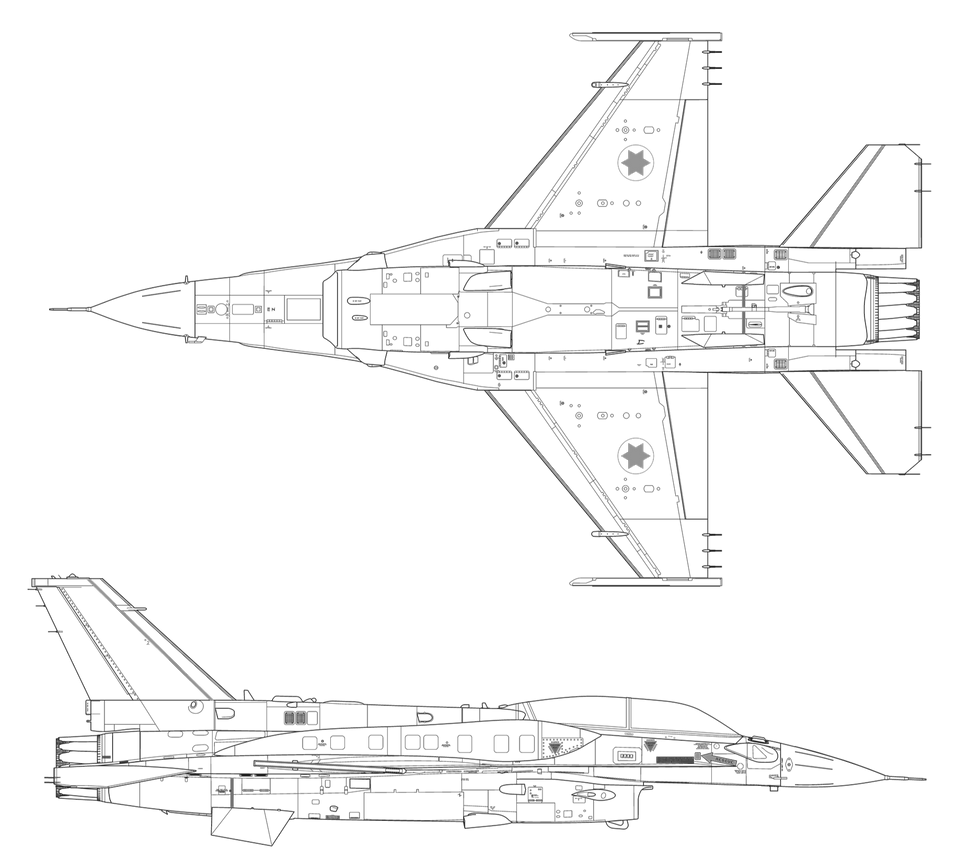

Line drawings showing, superimposed kit and actual nose profile and details is provided below. These drawings were prepared especially for this article by Netanel Deri who also provide the graphic for the kit's accurate decals.

Small parts such as the chaff/flare dispensers and ejection seat are of incorrect dimensions which result in excessive gaps or are rendered unusable. The kit is akin to a limited run kit release and suffers from very soft plastic parts (landing gear struts) and excessive injection molding risers that are a nascence to remove. I diverged from the kit's assembly sequence in order to avoid breakage of the smaller items during the filling and sanding operations accompany the assembly of the major components of the kit. The assembly sequence I used was to first assemble and correct the upper fuselage “hump” fairing, assemble and paint the intake ducting, wheel well and landing gear, cockpit assembly and painting, nose section correction, exhaust section painting and assembly, upper fuselage fairing and cft installation, control surface attachment, radome detailing, canopy detailing, painting, decaling, armament and final assembly.

Stage 1 - Fuselage upper spine corrections:

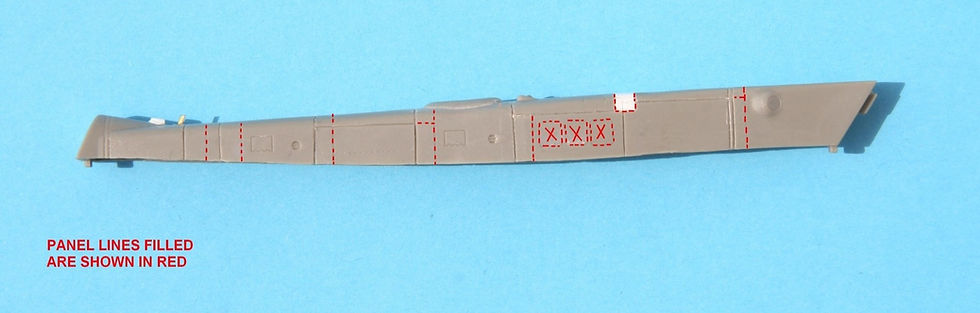

The upper fuselage spine has panel line location errors that require re-scribing to correct.

The spine fairing halves P24 and P25 match the scale drawings in height and width and the locations of the aft most RWR bulges and forward most vertical lines are located correctly. Vertical lines in between are incorrectly located which results in antenna array panel P23 being positioned 3mm aft of the required location. The chaff/flare dispensers and refueling opening were filled with Cynoacrylate cement and later represented using decals. The forward vent molded to the right side of the hump was shaved off and repositioned per drawings. Antennas and intakes attached to the upper spine are left off for installation just prior to painting in order to avoid their breakage (see slides below for additional views of spine fairing corrections).

Stage 2 - Wheel Well and Landing Gear Installation:

The forward (J6 + J7) and aft (C21 + C48) intake ducts were assembled and painted separately Tamiya X2 gloss white. The forward and aft ducts then were assembled together and attached to the lower fuselage as one section. Forward intake halves P1 and P2 glued to the lower fuselage, separate of the ducting with sheet plastic shims used to eliminate gaps.

To enable the addition of the main landing gear after all the major parts were assembled, the aft end of the keel beam (part C47) was removed, and part U1 was separated at the panel line just forward of the wheel wells.

Stage 3 - Nose Landing Gear Corrections:

The Sufa's nose wheel is wider than that found on previous versions of the F-16A/B/C/D.

MM4 +2XMM5 wide nose wheel is correct for the Sufa and requires filler at its center line.

The nose gear was detailed with electrical strands of electrical appliance wire and reinforced with a metal rod inserted through a hole made in the gear strut and wheel.

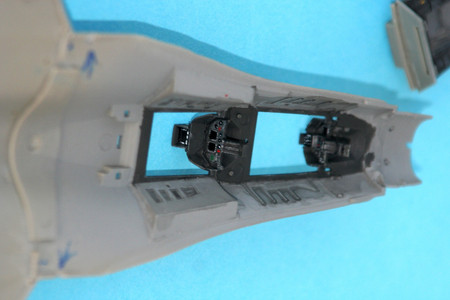

Stage 4 - Cockpit Detailing & Painting:

F-16i Sufa Cockpit Photos

The ejections seats in the kit were poor in fit and detail and were replaced by Squadron's True Details Aces II ejection seats.

The fuselage side walls and cockpit tub were airbrushed Humbrol 140 (f.s.36231) cockpit gray. The side consoles and forward instrument panels were painted Humbrol 32 dark gray and given a wash of Humbrol 33 flat black. Knobs and other raised detail were given a dry brush of flat white.

Stage 5 - Nose Contour Correction:

Kinetic's upper nose contour (with part C59 attached) is 1mm lower than Tamiya's, at the radome attachment line. To raise the Kinetic kit's contour line upwards, cuts were made to the nose section where panes C10 and C12 aft end is located.

Only after the radome is affixed to the upper nose section (part C59) can the lower nose section be lifted upwards to meet the radome's lower contour line. A rasp file was used

to remove plastic from the bottom of the cockpit tub in order to be able to raise the lower forward fuselage upwards. Avionics doors C10 and C12 were butted against the radome and sheet plastic shims were used to fill their aft ends.

Kinetic's Sufa parts breakdown is similar to Tamiya's F-16, which helps in correcting the kit's excessive nose droop. Drawings provided by Netanel Deri in the accompanying Airplane in Profile feature show the correct nose section angle in comparison the Kinetic's erroneous nose section.

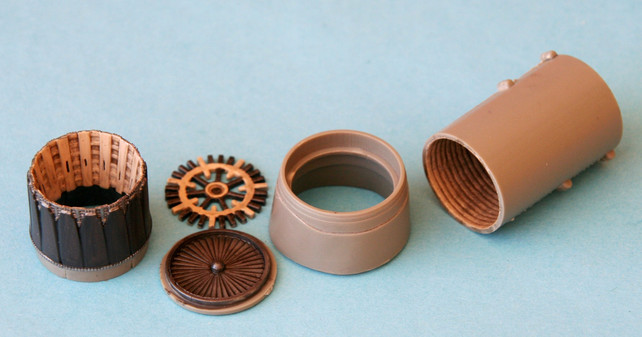

Stage 6 - Exhaust Nozzle:

Exhaust section parts J10, J13, D22 X2 ceramic coated areas were painted Humbrol 121 sand and the metal areas Xtracolor X508 Burnt Iron. The external leaves were painted Humbrol 67 gray and rubbed with 4B pencil with the aft end metal areas painted X508 Burnt Iron. All the exhaust section parts were given a wash of X-19 clear smoke and sealed with acrylic clear flat.

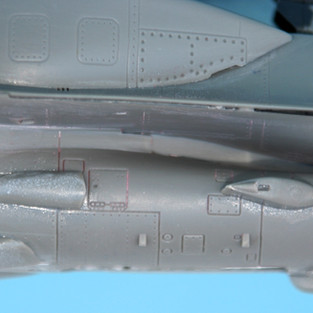

Stage 7 - Upper Fuselage CFT Alignment:

I used the CFT’s attachment relative to the gun muzzle as reference for positioning. I attached the left CFT to the fuselage using just a touch of Cynoacrylate cement at the upper lip and aft end of the CFT. Once the Cynoacrylate cement had set, I ran Tamiya liquid cement along the top and bottom joints of the CFT. To fill the gap atop the gun muzzle, I applied two part 5-minute epoxy glue and removed the excess with a Q-tip swab whetted with water.

Stage 8 - Control Surfaces:

Vertical fin part C51 leading edge was missing plastic at it's leading edge. A new fin leading edge was cemented into place, made from Evergreen no.100 (.010"X.020") plastic strip and the pointed probe replaced with a sharpened metal rod.

Brass wire pins were used to strengthen the joints between the leading edge flaps (C19 and C20), trailing edge flaps (C54+C71 and C55+C70) and the wings. The same was done to join the rudder with the vertical stabilizer.

Stage 9 - RWR location:

Installation of forward fuselage RWR sensors MM4 and MM5 is vague and required photos of the actual airplane for correct placement. Inlet lip sensor J8 was attached with Cynoacrylate cement and required gentle persuading and filler to fit smoothly with the rest of the intake duct.

The RWR/intake position lights P7/P9 and P6/P8 intake locating pins are too far forward. Trim off the forward locating pin and use only the aft pin to locate the position light sensors. MM9 auxiliary intake lip should be positioned aft and parallel to the panel line forward of it.

Stage 10 - Horizontal Stabilizer Attachment:

Horizontal stabilizer soft plastic hinges were drilled through and metal rod inserted for reinforcement. The kit’s plastic static discharges were replaced with .30mm thick nylon fishing wire.

The horizontal stabilizers were attached with trailing edges lowered such that the inboard tip of the stabilizer still remains guarded by the inside the vertical surface of the aft fuselage.

The right side aft fuselage vent fairing part P19 is not called out by number and position is not shown, it is to be positioned fwd of the right side RWR sensor.

Stage 11 - Wing Tips:

The Sufa uses part M6 missile rails at the wing tips which can be used for launching both AIM-9L/M Sidewinders and AIM-120 missiles. Nylon fishing line .030mm thick, 3.5mm long replaced the kit’s plastic static discharges. At the left wing leading edge, the forward sensor part P11 was cut and rotated 180 degrees so its flat face points upwards.

Stage 12 - Radome Detailing and Installation:

I found the kit's radome lower contour as being a contributing factor to the excessive droop, instead I used a flat bottomed radome from a Hasegawa F-16, which fit perfectly to Kinetic's nose contour.

Radome electrical diverter strips were made from Evergreen #100 (.010"X.020") plastic strips; 35mm long at the top and bottom and six others 15mm long. Syringe and metal rod were used for the pitot tube with metal rod with sharpened tips used for AOA probes.

Stage 13 - Assembly Completed & Ready for Paint:

Stage 14 - Canopy Tint and Detailing:

To the kit’s canopy I added helmet HUD sensors & wires. The forward windshield was tinted using Tamiya clear yellow diluted with Johnson’s Future Klear.

Stage 15 - Camouflage Painting:

The entire model was painted Testors Model Master f.s.36375 Light Ghost Gray. In addition to being the undersurface color for all IAF F-16's it also served as a primer coat for flaw detection. The areas due to remain Light Ghost Gray were masked and the wing, vertical fin and horizontal stabilizer leading edges; radome; wing tip AIM-120 missile rails and antenna covers were painted Humbrol no.126 gray (f.s.36270).

The colors I found to best represent the colors used on IAF F-16's are Xtracolor X105 sand, Humbrol 118 brown on the airframe, Humbrol 119 red-brown on the CFT's, and Testors Model Master 2049 RAF Sky Type S (ANA610) green. Paint overspray was minimized by extensive masking with Tamiya tape and some overspray on the gloss sand removed using a pencil eraser. The engine metal ring and the APU exhaust vent ahead of the wheel well were painted Xtracolor X506 Gunmetal.

To avoid discoloration and chipping of the light colored paint due to handling, I used clear plastic wrap in areas where I had to hold the model.

With camouflage complete, the nose and main landing gear, wheel wells and doors were installed and sprayed with Tamiya X2 gloss white diluted with lacquer thinner. Next to be masked off and brush painted were the tires and cockpit sill using Humbrol 85 semi-gloss black. Due to the Sky Type S green propensity to discoloration due to handling and low abrasion tolerance, I applied a coat of Future clear gloss to the entire model prior to initiating weathering. Weathering consisted of Tamiya X19 smoke diluted with alcohol and applied to panel lines using a 000 brush.

Stage 16 - External Stores:

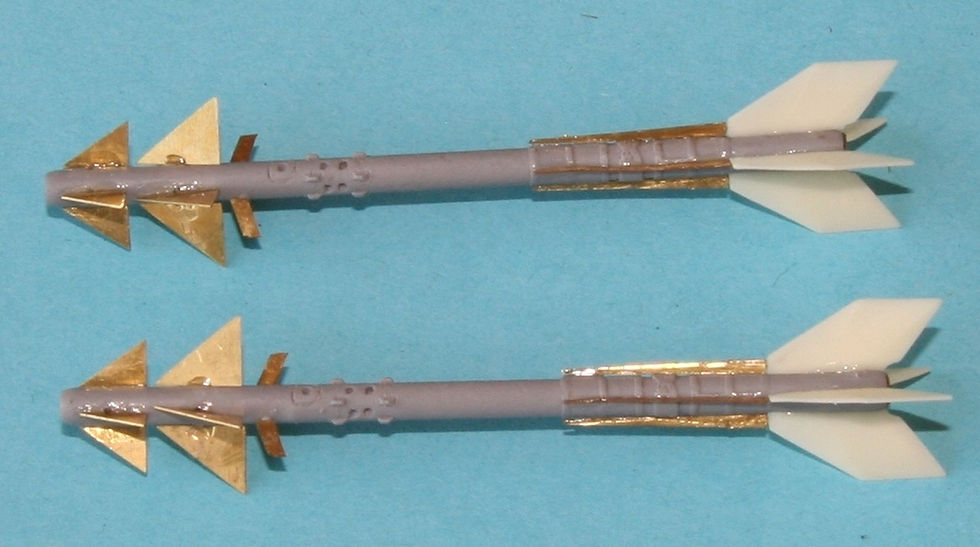

Although the Kinetic F-16i kit contains very accurate, wonderfully molded weapons, the original kit release did not contain the more common Python 4's and Mk.84 Paveway II laser guided bombs seen carried by the Sufa, Their 2020 reissued kit addresses this external stores shortfall. In this review I used IsraCast Python 4 missiles set 48023 and GBU-10 Paveway IIs from Hasegawa Weapons set X48-8.

Fuel tanks were painted Testors Model Master f.s.36375 Light Ghost Gray, weathered with a wash of Tamiya X19 Smoke and serialized using 1/72 F-16 identification numbers.

The kit provided AIM-120 missile fin leading edges were sharpened with a sanding stick. The missile body painted Humbrol 127, the radome Tamiya X-2 gloss white, fins Xtracolor X508 Burnt Iron and exhaust Humbrol 70 Red-Brown. Stencils are from the kit and the wash Tamiya X19.

The Python 4's are painted with Humbrol 128 fuselage, center fins Humbrol 147, forward seeker section X508 Burnt Iron, fins Xtracolor X502 Natural Steel with additional missile details painted Humbrol 11 Silver, 220 red, 2 green and Humbrol 130 white. To the forward end of the Pythons, a light blue reflective lens was attached using clear 5-minute epoxy. The Python 4 missile rails provided in the kit were painted Humbrol 127 with Humbrol 126 pylons.

Step 21 instructs the modeler to use the kit provided AN/AAQ-14 Lantrin pod which is not used on IAF F-16's. The IAF uses the Rafael Lightning II Pod on the right side intake pylons and this is provide in the kit as parts HH1, HH2, HH5 and HH6. Note that the aft end of the Lightning pod’s intake should line up with the aft end of the pod.The Lightning II pod and the Lantrin navigation pod and its pylon were sprayed Testors Model Master f.s.36118 Gunship gray, panel lines enhanced with a wash of X-19 smoke and decaled with kit decals using and photos of the actual pods for decal placement and additional painting. Gold leaf decal strips were used for the pods vents located at the aft end of each pod.

AN/AAQ-13 Lantrin navigation pod shown in the kit's instructions (parts HH3 & HH4) is used by the IAF on the left side of the intake and it’s pylon is made up of kit parts H15 and H17, (not H17 and H19 shown in the instructions).

A pair of GBU-10 Paveway II seeker laser guided bombs were obtained from Hasegawa's 1/48 scale weapons set X48-8. Since I intended to depict a July-August 2006 Second Lebanon War Sufa, the forward and aft fins were painted Humbrol 155 Olive drab; only after the war did the IAF begin using light gray fined LGB's. The Mk.84 bomb center section was painted Testors f.s.34102 medium green. Forward fin attachment band was painted Humbrol 170 red brown with Humbrol 16 Gold Leaf band painted aft the forward fins.

Stage 17 - Decal Application:

The decals provided in the kit were of excellent register, color and durability. The sole exception was the yellow used on the "rescue" arrow and warnings decals located on the nose section. I used equivalent replacements found in IsraDecal Sufa sheet IAF- 54, along with tail numbers 253. The Negev squadron vertical fin marking need to be touched up at the static discharge riser locations. I found that the blue used in Kinetic's star of David roundels matches the blue used on the fin motif and cut out several segments to complete the tail markings. All decals were affixed to the model using a brush layer of Pledge "Future" floor finish.

The kit's upper wing roundel placement location is incorrect; the center line of the star of David is to be placed 24mm from the wing-fuselage joint and the Star’s lower horizontal line 13mm above the wing aft walkway panel line.

Stage 18 - Final Assembly:

Once the model was painted, weathered, decaled and armed the model was sprayed with a semi-matt coat of clear consisting of a mixture of Tamiya X21 flat base added to Johnsons Klear and diluted with 70% pharmaceutical alcohol. The last items to be cemented to the model include reflective lenses in the nose gear door taxi lights, Lightning II pod, HUD and upper fuselage position lights. Additional items added include: Step 7 partsC66 and 2 of part Z3, Step 8 Z2 position lights; Step 15 blade antenna fwd of vertical fin and Step 17 HUD and reflective lens. The left wing tip and left intake position lights were painted Humbrol 30 Deep Red with corresponding items on the right side painted Humbrol 222 metallic blue.

Kinetic 1/48 F-16i Sufa - Completed Model Photos:

Recommended Reference:

IsraDecal Publications – F-16I Sufa in IAF Service

Note: A third edition of the IsraDecal Publications F-16I Sufa in IAF Service book is due for release in 2020.

Acknowledgements:

Ra’anan Weiss of IsraDecals, Netanel Deri of Sky’s Decals, Aviation Photographer Ofer Tzidon, Ahat and Negev squadron personnel and the IDF Censorship Borough.

The contents of this article have been reviewed and approved by the IDF censorship borough.

If you like this article and want to support my efforts in maintaining this web site you may make a donation through my PayPal account yoave@elal.co.il

Thank you,

Yoav Efrati

A great build of an iconic aircraft. Quite an inspiration for my Academy 1/32 waiting in the shelf.